Analysis with full diagnostic reporting…

Keeping machines in tip-top condition allows you to maximize their potential.

The vibration analysis service provided by Machine Tool Technology (MTT) is a system of condition monitoring that is both a predictive maintenance and a fault diagnostic tool.

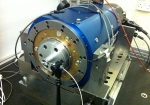

Using vibration analysis our engineers will identify early problems with rotating elements including ball screws, bearings, gear boxes, and motors.

The identification of potential problems, such as defective bearings and misalignment, without the need to disrupt production, makes you better placed to take corrective action before a critical failure has a major impact on machine up-time.

Quality and surface finish can also be enhanced by monitoring spindle vibrations. Spindle vibration will result in a one-to-one form error being created on the surface of the component.

If you feel that the surface finish is an issue for you then MTT can analyze spindle vibration as a standalone service or, as part of its comprehensive spindle analysis package.

In the case of our full machine tool modal analysis procedures, customers are provided with specific spindle speeds to avoid as a result of the machine’s resonant frequencies.